- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 6 Author: Site Editor Publish Time: 2026-01-29 Origin: Site

You can see the biggest difference by how each knitting machine makes fabric. Circular knitting machines have a round needle bed. They make seamless tubes fast and easily. If you learn to set them up well, you can work much faster. They can be up to 50 times faster than old ways. Flat knitting machines have straight needle beds. They help you make special designs and tricky patterns. You should think about the machine’s shape, the kind of knitting you need, and what you want to make.

Circular knitting machines make tubes without seams very fast. They work well for things like socks and T-shirts.

Flat knitting machines have needle beds that are straight. They help you make detailed designs and special patterns. These are great for fashion items.

Think about what you need to make before picking a machine. Circular machines are good for making lots of items. Flat machines are better for special designs.

It is easier to take care of flat knitting machines. You do not need much training to use them. They are easy to use.

The price is different for each machine. Flat knitting machines usually cost more. But they let you make high-quality custom items.

Flat knitting machines have a straight needle bed. The bed has small slots for the needles. A cam system or computer moves the needles. These machines let you knit with high accuracy. You can make hard patterns and shapes because of the V-bed setup. This design lets you use many knitting ways, like knit, miss, tuck, and transfer. You can make cool textures and shapes with these machines. Flat knitting machines are not like circular knitting machines. Circular knitting machines use a round needle bed. The straight bed helps you make flat panels and shaped clothes.

Tip: Flat knitting machines let you control each stitch. You can change patterns and shapes easily.

Flat knitting machines can make many kinds of fabric. You can knit jersey, rib, and interlock fabrics. Each fabric has its own use:

Fabric Type | Common Uses |

|---|---|

Jersey | T-shirts, activewear |

Rib | Sweaters, fitted garments |

Interlock | Comfortable clothing, activewear |

These fabrics are stretchy, comfy, and do not wrinkle much. They stretch in different ways, so they are good for sportswear and tight clothes. Flat knitting machines let you change the fit and feel of clothes. You can make clothes lighter and lower returns from bad fit. You can also knit shaped clothes, like rib clothes with color patterns, intarsia, fair isle, and argyle designs.

Flat knitting machines are used in many places. Here are some common uses:

Fashion clothes: You can knit sweaters, scarves, and other clothes for top brands.

Sports and special fabrics: You can make seamless sportswear with special features.

Medical and health fabrics: You can knit compression clothes and wound covers.

Industrial and car fabrics: You can make strong fabrics for cars and factories.

Custom home items: You can knit covers and throws for homes.

Flat knitting machines help you make custom pieces and shaped clothes. You can use weft knitting to make special designs. You can also mix weft and warp knitting for cool effects. These machines give you lots of choices and control for many jobs.

Circular knitting machines use a round needle bed. This shape lets you knit in a loop. The needles move around and grab yarn. They make loops as they go. You can make tube-shaped fabric with no seams. Flat knitting machines use a straight needle bed. They are better for flat fabric and special shapes.

Circular knitting machines use a round needle bed. They make tube-shaped fabric with no seams.

Flat knitting machines have a straight needle bed. They work best for flat fabric and custom designs.

The round shape helps you knit faster. It also makes the fabric even. You can set the machine to control yarn tension. You can also change the size of the loops. This keeps your fabric smooth and neat.

Circular knitting machines can make tubes with no seams. The machine knits in rounds. You do not need to sew pieces together. This way, the clothes are strong and comfy. There are no weak seams. The fit is better.

Advantage | Description |

|---|---|

Seamless Construction | No sewing needed. Clothes are stronger and last longer. Good for stretchy things like socks. |

Continuous Production | Machine works in rounds. You can knit faster and stop less than with flat knitting. |

Ergonomic Benefits | Weight spreads out better. Your hands and wrists get less tired on big projects. |

Fewer Seams | Clothes look nicer and feel better. Fewer seams mean less chance of breaking. |

Seamless clothes feel soft and fit well. You do not get chafing. You can move easily. These clothes last longer. There are fewer spots that can wear out. You can knit stretchy and airy fabric. These are good for sports and medical things.

Seamless clothes feel better because there are no seams.

They fit well and move with your body.

Seamless clothes use good materials. They last longer and do not wear out fast.

Circular knitting machines work very fast. Most knit at 1.5 meters per second. Some go up to 2.0 meters per second. A 30-inch machine can make 96 meters of fabric each minute. This is great for making lots of fabric.

You can make long pieces of fabric fast. This saves money when you need a lot.

You can make different kinds of fabric, like ribs and double jersey. This makes clothes look and work better.

You can knit T-shirt fabric, tubes for medical use, and special car fabric. You can make socks, T-shirts, underwear, and compression stockings quickly. You get more items in less time. This helps you save money and fill big orders.

Tip: If you want to knit many things fast, use circular knitting machines. They make seamless clothes quickly and easily.

When you look at knitting machines, you notice speed is different. Circular knitting machines are very fast. They can knit lots of fabric quickly. These machines make many rows at the same time. You can finish big orders fast. Flat knitting machines are slower. They let you control your work more. You can make special patterns and shapes. If you want to knit small batches, flat knitting machines are good. They help you make unique designs.

Machine Type | Speed and Efficiency Characteristics | Ideal Production Volume |

|---|---|---|

Circular Knitting | Makes fabric quickly. Good for big orders. Knits many rows at once. | Large volumes |

Flat Knitting | Slower but great for detailed work. Good for special designs. | Smaller batches |

Circular knitting is good for socks, T-shirts, and sportswear. Flat knitting machines are best for fashion or medical items. Both machines help you knit. You should pick the one that fits your needs.

Flat knitting machines are easy to use. You can change settings quickly. You do not need much training. The controls are simple. You can switch patterns or yarns fast. You make fewer mistakes with these machines.

Easy controls mean less time to learn.

Simple use helps you avoid mistakes.

Circular knitting machines need more care. You may need special skills to fix them. If you want to knit many things, flat knitting machines are easier to adjust.

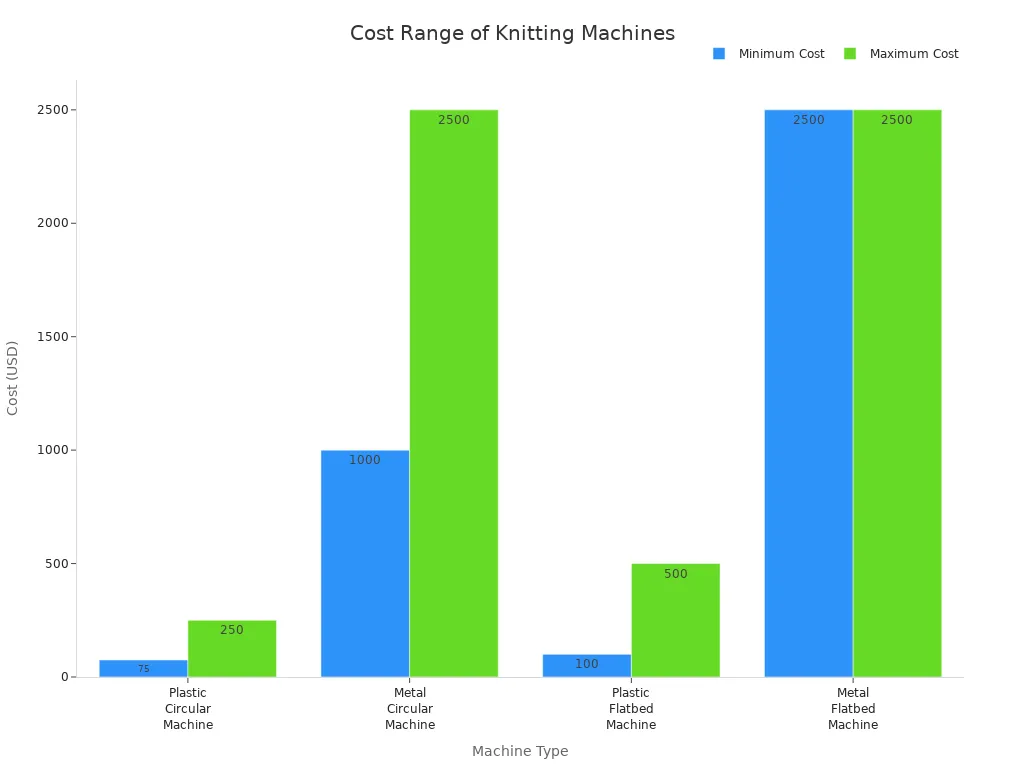

Think about cost before you buy a knitting machine. Flat knitting machines have many prices. A plastic flat-bed machine can be $100 if used. New ones can be $500. Metal flat-bed machines with more features can cost $2,500 or more. Circular knitting machines also have different prices. A plastic circular machine can be $75 to $250. Metal ones can be $1,000 to $2,500. Some advanced machines cost over $120,000.

Machine Type | Cost Range |

|---|---|

Plastic Circular Machine | $75 - $250 |

Metal Circular Machine | $1000 - $2500 |

Plastic Flatbed Machine | $100 (used) - $500 (new) |

Metal Flatbed Machine | $2500 (new with features) |

Flat knitting machines are great for custom, high-quality items. They work well for special orders. Circular knitting machines save money when you need lots of fabric fast. Pick the machine that matches your business goals. Think about weft knitting, warp knitting, or seamless circular knitting.

First, think about what you want to make. Each knitting machine works best for certain things. Flat knitting machines are good for sweaters with hard patterns. They give you more control. Circular knitting machines are better for making seamless tubes. These are used for socks or T-shirts. Latch needle machines can use many yarn types and sizes. You can knit thick or thin fabric with them. You can also change the needle slots for your yarn. Before you pick a machine, check these things:

How much you want to make

What kind of fabric and design you need

How fast the machine works

How easy it is to fix and clean

How much money you have

You should also look at these things:

Gauge means how many needles are in one inch. This tells you how fine your fabric will be.

The number of knitting heads shows how fast you can knit. More heads mean faster work.

Machine width tells you how big a piece you can make.

Some machines do simple knitting. Others can do more advanced things.

Good software helps you make new patterns easily.

Pick a machine that fits your goals. If you want to make lots of seamless things, use circular knitting machines. They are fast and save time. Flat knitting machines are slower. But they let you make special designs and small batches. Look at this table to see the difference:

Machine Type | Speed of Production | Suitability for Large Panels | Versatility |

|---|---|---|---|

Circular Knitting | High | Ideal for batch production | Less versatile |

Flat Knitting | Lower | Time-consuming for large panels | More versatile |

Flat-bed machines let you knit across for special patterns. Circular knitting machines use seamless knitting for fast, even fabric. If you want to knit with lots of detail, flat knitting machines help you change each piece.

Feature | Flatbed Knitting Machine | Circular Knitting Machine |

|---|---|---|

Weaving Method | Uses a flat bed for horizontal weaving | Uses a round needle bed for tube fabric |

Fabric Types | Makes hard patterns and high-quality fabric | Makes even fabric for big orders |

Flexibility | Very flexible for custom and small batches | Not as flexible, but good for big jobs |

Production Speed | Slower, makes one piece at a time, but very exact | Faster, makes lots of fabric without stopping |

Try to balance cost and quality when you choose a machine. Check prices from different brands. Pick machines with strong parts so you fix them less. Think about how much you can sell the machine for later. Look at the total cost, including buying and fixing. Flat knitting machines cost more but make better custom things. Circular knitting machines help you make seamless things fast and save money for big orders.

Tip: Always match your money plan to your business needs. Picking the right machine helps you make better things and grow your business.

When picking a knitting machine, think about what you want to make. Circular machines are good for making tubes fast. They work well for making lots of things. Flat machines help you make special designs and hard patterns. You should look at your money, how much it costs to fix, and if the machine can work by itself.

Machine Type | Best For | Production Speed | Design Flexibility |

|---|---|---|---|

Circular | T-shirts, socks | High | Low |

Flat | Fashion, custom | Lower | High |

Tip: Pick the knitting machine that fits your business best. This helps you get good results.

You use flat knitting machines to knit flat panels. Circular knitting machines help you knit seamless tubes. Each machine works best for different types of clothes and fabric shapes.

You can knit simple patterns with circular knitting machines. If you want detailed or custom designs, flat knitting machines give you more control. You can change each stitch and create special looks.

You should use circular knitting machines to knit socks. These machines knit tubes quickly and make seamless socks. You get a smooth finish and strong fabric.

You do not need advanced skills to use flat knitting machines. You can learn basic controls fast. These machines let you knit many patterns and switch yarns easily.

You should think about what you want to knit. If you need bulk items, circular knitting machines work best. For custom or shaped pieces, flat knitting machines give you more options.